micrometer to measure pipe thickness|micrometer for tubing wall : ODM On rough surfaces, micrometers measure coating thickness above the highest peak. What Destructive Tests are Used for Paint Thickness Measurement? One destructive technique is to cut the coated part in a cross . Um ataque naval britânico liderado por Horatio Nelson é repelido.

{plog:ftitle_list}

31 de out. de 2023 · Showdown Mudryk SBC-Guide. Mykhailo Mudryk, Chelseas damaliger Rekord-Neuzugang für 88 Millionen Pfund, ist der neueste Superstar, der in FC 24 einen SBC erhalten hat. Und meine Güte, sieht diese Karte verschwitzt aus? 93 Tempo und 86 Dribblings sind die beiden Highlights dieser 85 OVR LW-Karte, und die Aussicht auf ein .

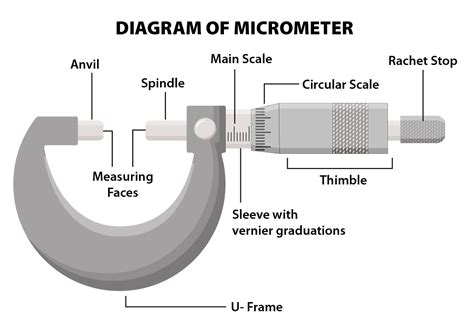

Electronic Outside Micrometers for Pipe, Tubing, and Flat Surfaces. Swap out the anvil on these micrometers for a better fit on curved and flat parts. Use the rounded anvil to measure the wall thickness of curved surfaces, such as pipe and tubing. Use the flat anvil to measure flat surfaces. On rough surfaces, micrometers measure coating thickness above the highest peak. What Destructive Tests are Used for Paint Thickness Measurement? One destructive technique is to cut the coated part in a cross .Step 1: Take the Measurement. Place your part between the measuring faces. Bring the measuring face towards the part by rotating the spindle. When you are close use rachet to press the measuring face against the part. You should . Industries measure thickness by a Micrometer. I as an Industry insider tried to explain how to use a micrometre. I have explained its parts, how to use it an.

Outside micrometers look like a clamp — a moving spindle comes together with a fixed “anvil” to measure the thickness or diameter of a part. Digital caliper-jaw micrometers are used to measure the inside dimensions of holes, tubes, pipes, or grooves, and have jaws that expand and contract. These micrometers are held at a parallel angle to . Micrometer is used to measure the bearing, pipe fittings, thickness of a metal, depth of a hole, pipe diameter, grooves, parts of machine, paper thickness, screw, etc. Choosing the right type of micrometer is the crucial thing when shopping for a new micrometer. Outside micrometer cannot measure the inside diameter of a bore at all.

These micrometers have a round anvil for measuring the wall thickness of pipe, tubing, and other curved surfaces. Outside Micrometers for Pipe and Tubing with Calibration Certificate. These micrometers come with a calibration certificate traceable to NIST that states they've passed a test for accuracy. Tube Micrometer. A tube micrometer is a measuring device that has a rounded anvil and a flat spindle. This type of micrometer is designed specifically to measure the wall thickness of tubing and pipes. Tube micrometers are available with four different types of anvils, which include pin, spherical, and cylindrical.

mmd5np pinless lcd moisture meter

Use the round face on the anvil to measure the wall thickness of pipe, tubing, and other curved surfaces. . Outside Micrometers for Pipe and Tubing with Calibration Certificate. These micrometers come with a calibration certificate traceable to NIST that states they've passed a test for accuracy.Connect measuring tools with SPC output to a processor for uploading data. . Outside Micrometers. Apply even pressure to objects to measure thickness more precisely than thickness gauges. 201 products. Bore Gauges. Insert into a hole and expand the contacts to measure diameter . Color code micrometers by calibration date, precision, or .The metals fabrication business is one of the oldest industries in the world. Large mills are automated, but some smaller mills still rely on hand-held micrometers to gauge metal thickness. AR200 laser measurement sensors are ideal for measuring steel strip thickness to fine resolutions. Steel passes between two opposing non-contact laser sensors.Micrometer; OEM Microscope Components for Integration; . Ultrasonic thickness gauges can provide advantages when a mill operator or end user needs to verify wall thickness of a pipe or tube, since the measurements are not limited to the accessible ends of the pipe. . these gauges can measure most metal tube and pipe walls ranging from less .

Here’s an example: To measure the threads on a ¼ inch male pipe thread (MPT), measure the very outsides of the thread, then subtract ¼ inch of the outside diameter (OD) measurement to account for the thickness of the pipe wall on either side. When measuring a female pipe thread (FPT), measure the OD of the pipe itself and subtract ¼ inch . Once the pipe is cut, use a ruler, caliper, or micrometer to measure the thickness of the pipe’s wall directly. What is the difference between male and female threads? Male and female threads refer to the two types of threads used in plumbing and various other applications for connecting pipes, fittings, and other components. These micrometers have a special anvil and spindle to allow them to measure the opposite sides of a thread. The anvil has a double v shape while the spindle is pointed. They have an overall measuring range such as 0-1” or 1-2” like a standard micrometer but also have a range of threads per inch or mm that they are capable of measuring. The thickness of the wall of a pipe or tube. Types of micrometers. Different types of micrometers measure different things. The main types are: An outside micrometer, which measures thickness; An inside .

Choose from our selection of Mitutoyo outside micrometer sets, economy outside micrometer sets, Starrett outside micrometer sets, and more. In stock and ready to ship. BROWSE CATALOG . Use the rounded anvil to measure the wall thickness of pipe, tubing, and other curved surfaces. Use the flat anvil to measure flat surfaces. Electronic Outside .

Micrometer; OEM Microscope Components for Integration; Industrial Microscope FAQ; Customized Solutions; . If you’re looking to measure the thickness of a pipe, an ultrasonic thickness gauge should be used. A handheld thickness gauge, such as the 27MG gauge, will offer accurate measurements from one side of metal pipes and parts that are .

This micrometer comes with a calibration certificate traceable to NIST that states it has passed a test for accuracy. Switch out anvils depending on the shape of the item you're measuring. Use the rounded anvil to measure the wall thickness of pipe, tubing, and other curved surfaces. Use the flat anvil to measure flat surfaces.. Micrometer has a friction thimble with a constant-force . Micrometer: Measures thickness and diameter: Using the right tools ensures accurate measurements. This is crucial for a proper exhaust system fit. Whether you use a tape measure, calipers, or specialized tools, precision is key. . To measure pipe thickness, you need the inner and outer diameters. The thickness is the difference between the .Micrometers: Measuring the wall thickness of a steel pipe can be done using a micrometer. Micrometers are precise measurement instruments that allow for accurate readings. Start by opening the micrometer and positioning the pipe between its spindle and anvil. Gently tighten the micrometer until the pipe is firmly held in place. Particularly well suited to measuring the thickness of tubes, micrometer limit mics come complete with two anvils and two spindles, functioning as effective snap gauges. The gaps correspond directly to the upper and lower tolerance levels. . Purpose-made for external measurement, V micrometers come complete with small V-blocks for the anvil .

Contents. 1 Key Takeaways:; 2 Importance of measuring brake rotor thickness regularly. 2.1 Evolution of rotor thickness in modern automakers; 2.2 Safety implications of worn-out or thin rotors; 3 When to check rotor thickness; 4 The process of measuring rotor thickness using a micrometer. 4.1 Multiple measurements in different spots; 4.2 Keeping a distance .

Here’s how to measure with a micrometer: Start by considering whether you want to measure a few pages (20 pages will suffice), or an entire stack/ream (from 100 to 200 pages). You can measure both ways with a micrometer. Then proceed by setting up the micrometer at the ideal thickness of the paper. A detailed guide to measuring internal or external diameters and depth with a Vernier caliperIf you're in need of a very precise length measurement, a Vernier caliper is going to be your best friend. This tool is used to measure internal. An inside micrometer is intended to measure the internal dimensions of a given part. Measuring the diameter of a hole or a tube might be a good reason to use an inside micrometer. . These are used to measure the thickness of a tube or a pipe. V-anvil micrometers have an anvil shaped like the letter “V” providing three evenly-spaced .

These micrometers have a round anvil for measuring the wall thickness of pipe, tubing, and other curved surfaces. Outside Micrometers for Pipe and Tubing with Calibration Certificate. These micrometers come with a calibration certificate traceable to NIST that states they've passed a test for accuracy.

Do you need to know a tube’s wall thickness? Ball contacts are used to measure wall thickness of tubes and other cylindrical components. Micrometers are available with one- or two-ball/radiused contacts. The one-ball/radius style may be used for inspection of wall thickness on tubing. Two-ball/radius contacts can inspect thickness between holes.

what is a micrometer for

18 de mai. de 2021 · About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

micrometer to measure pipe thickness|micrometer for tubing wall